The processes

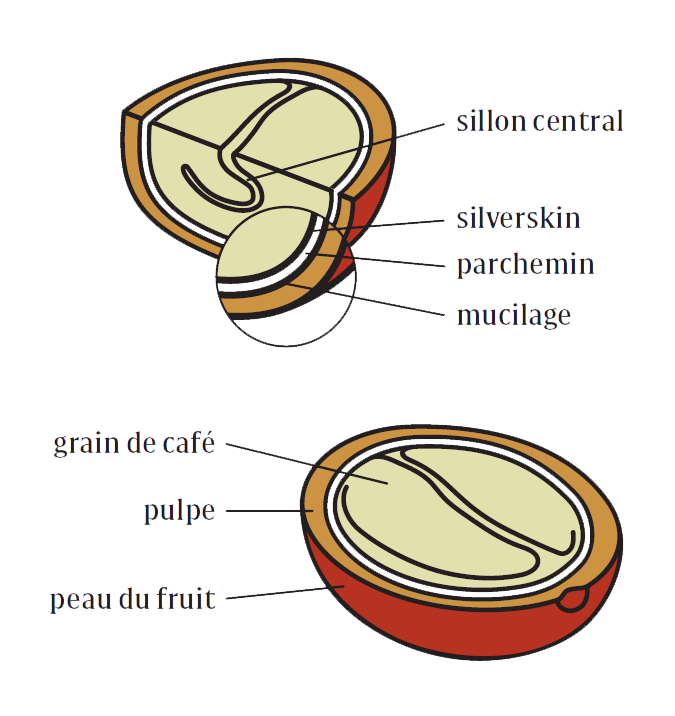

Coffee is the pit of a fruit – a cherry! The process refers to the extraction of the coffee bean from its cherry as well as the drying of it, in order to roast it and taste it. The impact of processes on flavor is significant and is important information to consider when choosing coffee. Although more and more different processes are emerging, with many variations, three basic processes can still be distinguished – the natural process, the washed process and the honey/natural pulped process.

Natural process

The natural process is the oldest method, requiring the least amount of equipment and water: the cherries are picked and spread out in the sun to dry. Some additional steps can be added before drying like fermentation inside the cherry, soaking to remove overdeveloped cherries, manual sorting to remove impurities and underdeveloped cherries, etc. No matter what step is added, the basic principle always remains the same.

When a fruit is exposed to sunlight, it ferments and allows flavors to develop in the coffee bean. About 30 days of sun drying are necessary for the humidity level to be low enough (around 12%) and for the grain to become stable without being brittle. The natural process seems rather simple at first glance, but it can easily take a negative turn. This is why it must be carried out with great attention, so that the result is of high quality by obtaining uniform drying of the grains and without mold.

Characteristics of the natural process:

- Less pronounced acidity

- A creamier body

- Sometimes fermentation aromas.

photo credit: Crop to cup

Washed process

In this method, the coffee cherry is removed using a machine called a pulper, which slides the coffee bean out of its cherry pulp. However, the pulper does not remove all layers of the coffee bean.

Around the grain, three layers remain: mucilage, parchment, and the skin of the grain (silverskin). Mucilage, a layer of pectin encasing coffee beans, can be effectively removed through fermentation. The grains thus spend several hours fermenting, and this is where it can become complex: dry fermentation, in water, anaerobic (without air), long, short... the combinations are endless, and this step constitutes crucial work for producers who can use this fermentation to bring out certain elements of their grains.

After fermentation, the pectin layer now partly disintegrated, the coffee is washed with clean water to remove residues and prepare it for drying. This is when the coffee beans, still wrapped in their parchment, are laid out in the sun to dry. Drying of washed grains takes almost two weeks to complete.

Characteristics of the washed process:

- Cleaner, more delicate flavors

- A more frank acidity.

photo credit: Semilla coffee

Honey or natural pulped

Pulped natural and honey are two terms for the same process, adopted for different reasons in different countries. In this process, the cherry is pulped from the start, similar to the washed process. However, instead of removing the mucilage through fermentation and washing, the coffee, with its mucilage, is left in the sun to dry.

Why call it honey? The reason is simple: the mucilage which then envelops the coffee is mainly composed of sugar, giving it a texture similar to that of honey. The sugars in the mucilage caramelize around the coffee bean during drying.

There are different grades of honey, generally characterized by color: white, yellow, red and black. The degree of honey is influenced not only by the amount of mucilage left on the grain, but also by the total drying time. The darker the color, the more mucilage there is and the longer the drying time.

Characteristics of the honey or natural pulped process:

- tends to offer the rounder body of the natural while

while retaining the delicacy of the washed - closer to the characteristics of a washed one for a white honey, or those of a natural one for a black honey.

Shelling

A crucial step remains before export, even after the grains have been dried and stabilized: hulling. Natural coffee persists in its dry cherry, honey in its mucilage, and washed in its parchment, elements that must be removed before roasting.

Shelling is carried out using a machine, through which the coffee beans pass several times, thus removing these superfluous layers. At this stage, the coffee beans are also sorted according to their size and density, ensuring increased uniformity.

After hulling, only the skin (silverskin) remains on the beans, but this layer will only be removed during roasting. It naturally detaches while the beans cook and is sucked out of the roaster. The silverskin helps maintain the freshness of the beans for an extended period of time.

The process is just one of many factors influencing the flavor of coffee beans. However, recognizing its impact on taste can help you make informed choices when purchasing coffee, while recognizing all the meticulous work that goes into the beverage.